Do you have questions?

Simple Flow Measurement

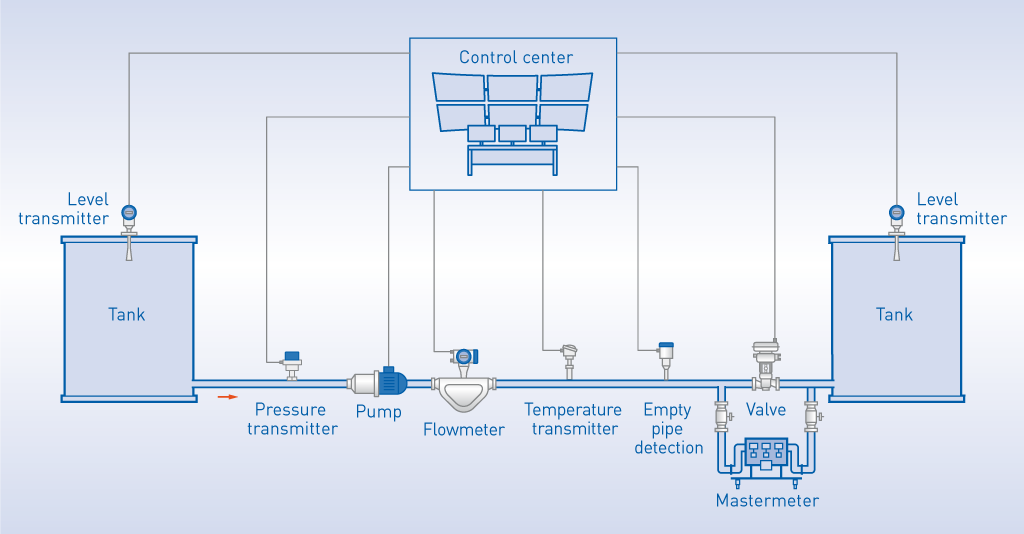

For the simplest liquid transfer solution, the supplier has a storage container which is connected to a receiving tank belonging to the user (purchaser), using a pipeline. This pipeline is typically equipped with a pump and valves, plus a calibrated flowmeter having a visible display of the flow total. By prior agreement, both parties agree to accept the readings taken from the flowmeter display, as visually recorded on site, as the measurement of the quantity of liquid transferred in the transaction.

To prevent gas pockets in the pipeline, the tanks must not fall below a minimum level, and the delivery must not cause the receiving tank to be over-filled. This is achieved by radar instruments that monitor the level in each tank, and provide alarm signals. The pipeline may additionally be used with other measurement sensors, such as pressure and temperature measuring devices, or an empty pipe detection sensor. The individual signals of all the measuring devices can be monitored and recorded by a process control system.